- Homepage

- Thermal Neutron Detectors

Thermal Neutron Detectors gas and with solid-state converter

“Neutron Technologies” LLC offers the manufacture of neutron detectors of four types.

1. Linear gas-discharge position-sensitive detector consists of neutron counters. It is a hermetically sealed thin-walled metal tube filled with gas, the conductive coating of the inner surface of which acts as a cathode. A wire with fixed ends stretched along the tube axis is used as an anode. The signal is read out with the charge division technique.

Technical features:

- neutron detector of any geometry with the size up to 1000x1000 mm can be manufactured on the basis of counters;

- modularity of the detector design - possibility to design large detection areas of arbitrary curvature (1 ÷ 30 m2 and more);

- high radiation resistance (not more than 0.01% per day).

- tube diameter - 8-25 mm;

- diameter of the anode wire 15-50 µm;

- detection efficiency - 60-90%.

2. Multi-wire proportional chamber

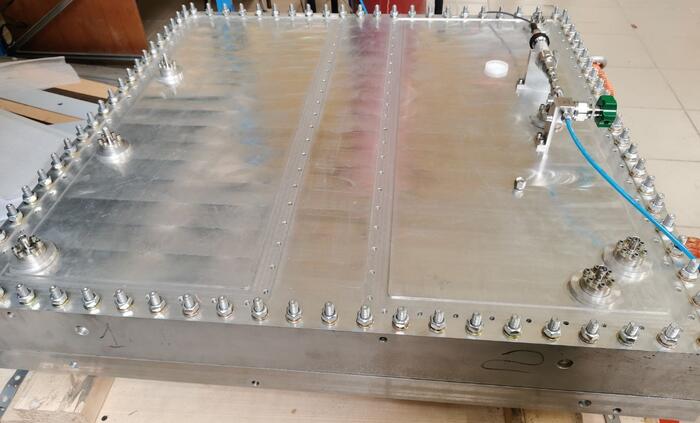

“Neutron Technologies” LLC offers the manufacture of two-dimensional gas-discharge position-sensitive neutron detectors based on a multi-wire proportional chamber.

According to their design, such gas-discharge neutron detectors can be made in the form of metal cylinders or chambers filled with gas.

Inside the volume there are electrode planes, an anode grid made of tungsten wires, and cathodes made of steel wires. The cathode wires are combined into strips connected to a delay line to record 2 coordinates.

Technical features:

- Low intrinsic noise (less than 0.5 Hz);

- Dead time of registration – 10-5 – 10-7 s;

- Time resolution – 5 µs;

- High radiation resistance;

- Sensitive area size from 100х100 mm to 600х600 mm;

- Diameter of the anode wire 8-30 µm;

- Diameter of the cathode wire 50 µm;

- Filling gas - He3, CF4;

- Detection efficiency 60-90%.

3. Neutron detector based on ZnS:6LiF(Ag) scintillator

The basic design of scintillation counters consists of a ZnS(Ag)/LiF scintillator bonded with an optical glue to an organic light guide with light-harvesting lenses and solid state silicon photomultipliers (SiPMs) at the ends. The counter is wrapped with fluoroplast tape, which serves as a diffuse reflector. The SiPM converts weak light flashes from a scintillator into electrical pulses that can be recorded by electronic equipment. Scintillation counters enable the extraction of 1 or 2 coordinates with 2 or 4 SiPMs.

Features:

- possibility to create sensitive detector volumes of arbitrary shape while maintaining high neutron efficiency;

- long service life of the counter without the need for maintenance;

- easy assembly and maintenance;

- sensitive area size - 5х50 mm, 10х50 mm, 15х100 mm, 50х50 mm, 10х200 mm, 100х100 mm, 50х120 mm;

- neutron efficiency - 50-80%;

- time resolution - 1 µs.

4. Monitor-profilometer

«Neutron Technologies» LLC offers the manufacture of specialized two-coordinate thermal neutron monitor - detector designed to visualize the direct passing beam and measure its intensity.

The conventional design of the detector is based on a multi-wire proportional chamber (MWPC), which consists of three electrodes. In the center is an anode grid made of tungsten wire. Two orthogonal cathodes made of steel wires combined into strips are symmetrically located about the central anode grid.

The monitor is designed to be used in a wide range of neutron flux density, so the detector can be filled with different gas mixtures containing helium 3He and nitrogen 14N.

The monitor-profilometer can be used in various neutron experiments: neutron diffraction, spectroscopy, reflectometry.

Features:

- the monitor can be used either on its own or as part of a measurement system;

- compactness - the thickness of the monitor along the beam does not exceed 60 mm;

- real-time measurement of beam parameters;

- long service lifetime - up to 5 years.